Newsletter Subscribe

Enter your email address below and subscribe to our newsletter

Enter your email address below and subscribe to our newsletter

Kanban System! Just as with any efficient production system, Kanban plays a pivotal role in streamlining processes and maximizing productivity. Originating from the acclaimed Toyota Production System, Kanban is a visual scheduling system that enables teams to visualize work, limit work in progress, and enhance workflow efficiency.

With Kanban, tasks are represented on cards and moved through different stages of production, providing a transparent view of work at every step of the process. By imposing limits on work in progress, teams can identify bottlenecks, reduce waste, and improve overall quality and delivery times. Learn more about how Kanban could revolutionize your workflow and take your productivity to new heights.

Background: There’s a common misconception that Kanban is a software development tool, but its roots actually lie in manufacturing. The concept of Kanban originated in Japan at Toyota as part of their renowned Toyota Production System. The word “Kanban” translates to “signboard” or “billboard,” which reflects its core function as a visual signaling system used to manage production.

The system was developed by Taiichi Ohno, an industrial engineer at Toyota, in the 1940s. Ohno was inspired by the supermarkets’ efficient reordering process, where goods were restocked based on actual customer demand rather than a fixed schedule. This realization led to the implementation of Kanban in Toyota’s manufacturing process to improve efficiency and reduce waste.

One: The integration of Kanban into Toyota’s production system marked a significant shift away from traditional manufacturing practices. Kanban served as a visual tool to limit work in progress and optimize workflow by enabling just-in-time production and inventory control. By only producing what was needed, when it was needed, Toyota was able to minimize waste and respond quickly to changes in demand.

For a successful implementation of Kanban, visualizing the workflow is crucial. This involves creating a visual representation of the entire process, from start to finish, allowing team members to see the status of each task at a glance. By using Kanban boards, cards, and columns, teams can gain insights into the flow of work and identify bottlenecks or areas for improvement.

An important principle of Kanban is limiting work in progress to optimize efficiency and productivity. By setting explicit limits on the number of tasks that can be in progress at any given time, teams can reduce multitasking, minimize context switching, and focus on completing tasks before taking on new ones. This helps prevent overburdening team members and ensures a steady flow of work through the system.

The art of limiting work in progress lies in finding the right balance between keeping the team productive and maintaining a sustainable pace. It requires discipline and a commitment to finishing what has been started before moving on to the next task. By respecting these limits, teams can deliver value more consistently and predictably.

The primary goal of Kanban is to enhance flow and throughput by continuously improving the workflow and eliminating waste. By focusing on reducing lead times, increasing delivery speed, and optimizing the overall process, teams can achieve higher levels of efficiency and customer satisfaction. Kanban emphasizes the importance of smooth, uninterrupted flow and encourages teams to identify and eliminate any obstacles that may disrupt it.

To achieve this, teams must pay close attention to the dependencies and relationships between tasks, as well as the handoffs between team members. By streamlining the flow of work and minimizing delays, teams can deliver value quicker and more effectively, leading to improved outcomes and higher customer satisfaction.

Kanban employs the feedback loop principle to continuously improve the process and adapt to changing requirements. By gathering feedback from team members, stakeholders, and customers, teams can identify areas for improvement, implement changes, and monitor the impact of those changes over time. This iterative approach allows for quick adjustments and course corrections, leading to better outcomes and increased efficiency.

To maximize the effectiveness of the feedback loop, teams must establish clear communication channels, encourage transparency, and foster a culture of continuous improvement. By embracing feedback as a valuable source of learning and growth, teams can adapt to evolving circumstances and deliver better results with each iteration.

All organizations implementing Kanban use some form of visual board to manage their work. The Kanban board is a visual representation of the work workflow, divided into columns that represent different stages of the process. These columns typically include labels such as ‘To Do’, ‘In Progress’, and ‘Done’ to indicate the status of each task. Team members move cards or sticky notes representing work items across the board as they progress through the workflow.

Using cards or tickets to represent work items on the Kanban board is a key practice in Kanban. Each card should contain crucial information about the task, such as a brief description, priority level, assigned team member, and due date. This helps team members quickly understand the status of each work item and prioritize their tasks accordingly.

Using cards or tickets effectively is crucial for a successful Kanban implementation. It ensures that all team members have clear visibility into the work that needs to be done and can easily collaborate on tasks. By providing crucial information on each card, team members can make data-driven decisions and keep the workflow running smoothly.

Another important aspect of Kanban is defining different types of work items based on their nature. These work item types could include tasks, bugs, features, or any other relevant categories specific to the team’s workflow. By categorizing work items, teams can prioritize effectively, allocate resources efficiently, and focus on delivering value to customers.

Kanban teams must carefully define work item types to ensure clarity and consistency in their workflow. This categorization helps in better organizing tasks, setting priorities, and improving overall efficiency. Assume that by clearly defining work item types, teams can streamline their processes and deliver high-quality results consistently.

Work items on the Kanban board move through columns representing each stage of the workflow, from initial request to completion. Columns help visualize the flow of work and identify bottlenecks or areas for improvement. Swimlanes, on the other hand, can be used to group work items by different criteria such as team member, project, or priority level, providing additional clarity and organization.

Work columns and swimlanes play a vital role in structuring and organizing work in Kanban. They provide a clear visualization of the workflow and help teams understand where each task stands in the process. By utilizing columns and swimlanes effectively, teams can improve their efficiency, collaboration, and overall productivity.

With pull systems, work is pulled into the next stage of the workflow only when the team has capacity and is ready to work on it. This ensures that work is not overloaded and that team members can focus on completing tasks effectively. In contrast, push systems rely on pushing work into the workflow regardless of capacity, often leading to bottlenecks, delays, and decreased productivity.

Using a pull system in Kanban promotes a more efficient and sustainable workflow. Team members can focus on completing work in progress before pulling in new tasks, reducing multitasking and improving overall quality. It ensures that the team works on tasks based on actual capacity and priorities, leading to smoother and more predictable delivery.

Not just limited to software development, Kanban has also found immense success in manufacturing environments. With its emphasis on visualizing work and limiting work in progress, Kanban has helped manufacturing teams optimize their production processes, reduce waste, and improve overall efficiency. By using Kanban boards to track tasks and identify bottlenecks in the production line, manufacturers can make real-time adjustments to ensure smooth operations and timely delivery of products.

Kanban is a versatile method that can be adapted to various industries, including service and IT. With its flexibility and focus on continuous improvement, Kanban has become a popular choice for service teams and IT departments looking to streamline their workflows, prioritize tasks, and deliver high-quality services to clients. By visualizing their work and setting explicit limits on work in progress, service and IT teams can boost productivity, reduce lead times, and enhance customer satisfaction.

Various service industries, such as marketing agencies, legal firms, and healthcare providers, have successfully implemented Kanban to manage their projects, improve collaboration among team members, and increase transparency in their operations. Similarly, IT departments have embraced Kanban to streamline their software development processes, respond quickly to changing requirements, and deliver value to customers more efficiently.

Tool for personal productivity and task management, Personal Kanban helps individuals visualize their workflow, prioritize tasks, and stay organized. By creating a Kanban board with columns representing different stages of work and using cards to capture tasks, individuals can track their progress, identify priorities, and maintain a clear focus on what needs to be done. Whether it’s managing household chores, planning personal projects, or tracking daily goals, Personal Kanban can help individuals stay on top of their tasks and achieve their objectives effectively.

With its success at the team level, organizations are increasingly looking to scale Kanban across departments and even entire enterprises. By establishing portfolio Kanban systems, organizations can gain visibility into all ongoing initiatives, prioritize projects based on strategic objectives, and align resources with business goals. Scaling Kanban allows organizations to improve coordination, enhance decision-making, and realize the full benefits of lean and agile practices.

Kanban offers a powerful framework for organizations to optimize their workflows, foster collaboration across teams, and drive continuous improvement at every level of the organization. By adopting Kanban principles and practices, businesses can adapt to changing market conditions, respond to customer needs more effectively, and achieve sustainable growth in today’s competitive landscape.

Considerations: When adopting Kanban, there are common pitfalls that teams may encounter. One of these pitfalls is insufficient training and understanding of the principles behind Kanban. To avoid this, it is crucial to invest time in educating team members about the methodology, its benefits, and how it should be implemented within the organization. Lack of communication and transparency can also hinder successful Kanban adoption. It is vital to ensure that everyone is on the same page and understands the goals and processes involved.

To: Measuring and managing flow efficiency is a critical aspect of Kanban adoption. By tracking key metrics such as lead time and cycle time, teams can identify bottlenecks and inefficiencies in the process. This data allows for informed decision-making and adjustments to improve overall workflow efficiency.

Avoid: Continual Improvement in the Kanban Process

Managing: Continual Improvement in the Kanban Process requires a proactive approach to identifying areas for enhancement. Encouraging teams to regularly review and reflect on their processes, collaborate on improvements, and implement changes is key to sustaining success with Kanban. By fostering a culture of continuous improvement, teams can adapt to changing requirements and optimize their workflow over time.

Kanban: Cultural Shifts and Change Management are fundamental considerations when implementing Kanban. The methodology often requires a shift in mindset and culture within an organization to embrace visualizing work, limiting work in progress, and focusing on continuous improvement. Resistance to change and lack of buy-in from stakeholders can hinder successful adoption of Kanban.

Many organizations that have successfully implemented Kanban find themselves looking for ways to advance beyond the basic principles and practices. This is where the Kanban Maturity Model comes into play, offering a structured approach to evolving and improving how Kanban is implemented within an organization. By following this model, teams can gradually mature their Kanban practices and achieve higher levels of efficiency and effectiveness.

Advancing beyond traditional Kanban also involves exploring how it can be integrated with other Agile methodologies such as Scrum or Lean. By combining Kanban with these methods, teams can leverage the strengths of each approach and create a more robust and flexible framework for managing their work. Any organization looking to maximize the benefits of Agile practices should consider how Kanban can be integrated into their existing processes.

Understanding the integration of Kanban with other Agile methodologies requires a deep understanding of both approaches and how they can complement each other. By combining the visual and flow-based nature of Kanban with the iterative and time-boxed approach of Scrum, teams can optimize their workflow and adapt more easily to changing requirements.

Digital Kanban systems offer a modern and efficient way to manage work visually, enabling teams to collaborate in real-time and track progress with ease. With the rise of remote work and distributed teams, digital Kanban tools have become important for organizations looking to streamline their processes and improve communication. Digital Kanban systems provide advanced features such as analytics, automation, and integration with other tools, making it easier for teams to manage their work effectively.

With advancements in technology, organizations can expect to see more sophisticated digital Kanban systems that offer greater customization, scalability, and integration capabilities. By leveraging these tools, teams can further enhance their Kanban practices and achieve higher levels of productivity and collaboration.

Methodologies such as Kanban are constantly evolving to meet the changing needs of modern organizations. Future trends and innovations in Kanban may include advancements in AI and machine learning to optimize workflow automation, as well as integration with IoT devices for real-time monitoring of production processes. By staying informed and embracing these innovations, organizations can stay ahead of the curve and continue to drive efficiency and innovation in their operations.

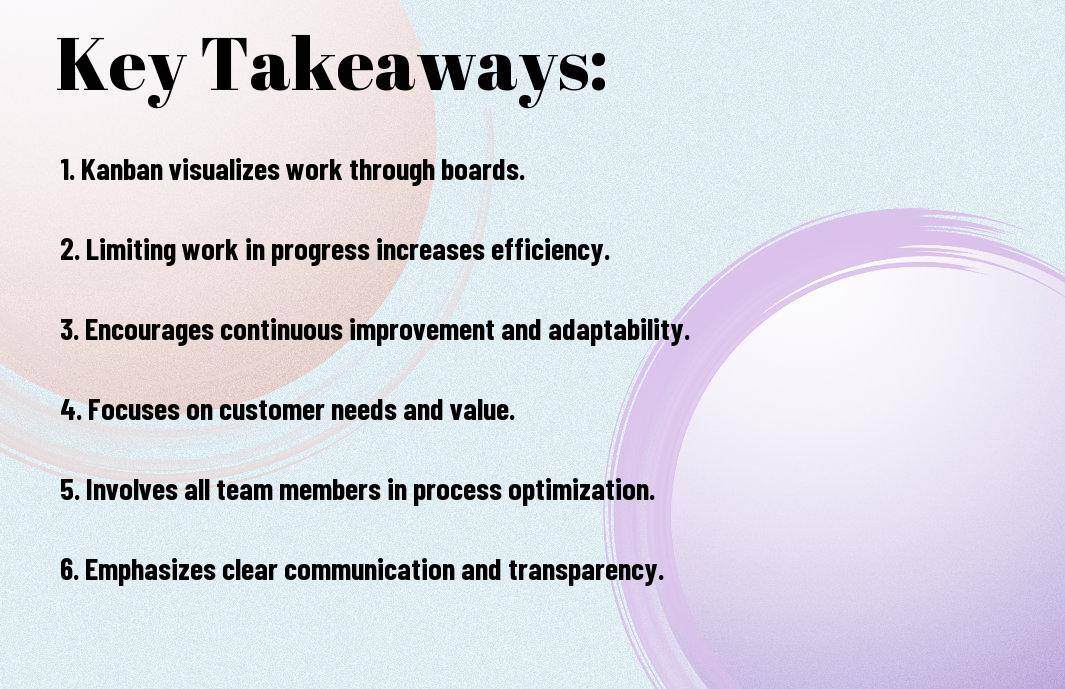

Considering all points discussed, it is clear that Kanban plays a crucial role in revolutionizing how work is visualized and progress is limited within the Toyota Production System. By using Kanban boards, teams can efficiently track work, identify bottlenecks, and continuously improve their processes. Through the principles of visualization, flow, and limiting work in progress, Kanban enables teams to optimize their workflow and enhance productivity.

To learn more about how Kanban can be effectively implemented to manage workflows and improve productivity, check out Kanban in Action: Visual Workflow Management. Embracing Kanban principles can lead to significant improvements in how work is managed and progress is tracked, making it a valuable tool for teams looking to enhance their efficiency and effectiveness.

A: Kanban is a visual framework used to implement agile methodologies in project management. It helps teams visualize work, limit work in progress, and maximize efficiency.

A: Kanban uses boards and cards to represent work items. Each card moves through different stages of a workflow, providing a clear visual representation of tasks and their status.

A: Limiting work in progress ensures that teams focus on completing tasks before starting new ones, reducing multitasking and improving flow efficiency.

A: By visualizing work, limiting work in progress, and continuously optimizing workflows, Kanban helps teams identify bottlenecks, reduce waste, and deliver value more effectively.

A: Kanban is based on the principles of “just-in-time” production, continuous improvement, and respect for people, which are core tenets of the Toyota Production System.

A: While Scrum is based on fixed-length iterations and predefined roles, Kanban is more flexible and focuses on continuous delivery, visualizing work, and optimizing flow.

A: To implement Kanban effectively, teams should start by visualizing their current workflow, setting work in progress limits, measuring and analyzing flow metrics, and continuously improving their processes.

Eisenhower Matrix – Dwight D. Eisenhower’s Strategy to Prioritize Tasks by Urgency and Importance

Mastering How to Think Like Elon Musk: Inside the Mind of a Visionary Genius

The 2 Minute Rule – David Allen’s (popularized) Trick to Overcome Procrastination and Start Tasks